Qingdao Steel Structure Prefabricated Building Maritime Carnival Project

Project description:

The Qingdao Maritime Carnival project is located in Phoenix Island Tourist Resort, Huangdao District. It is an all-round multi-functional large-scale commercial, residential and tourism complex. The steel structure roof is constructed by Xinguangzheng.

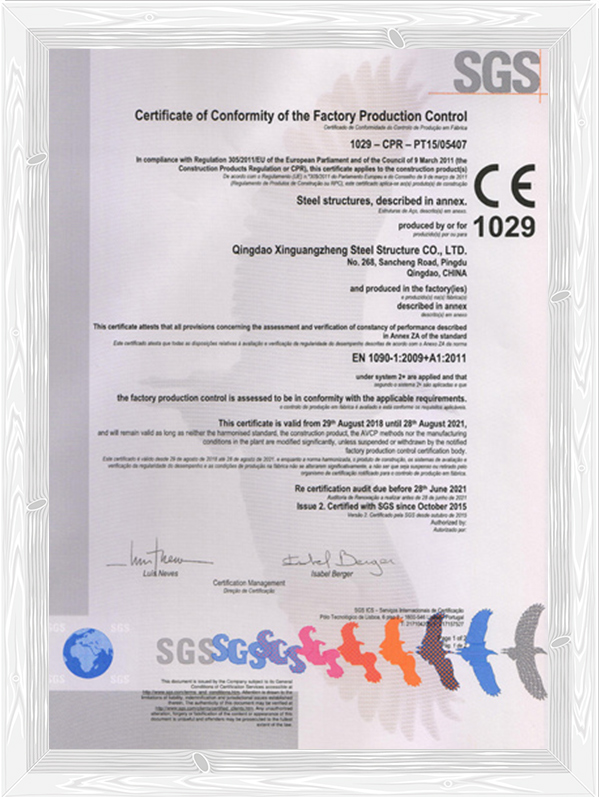

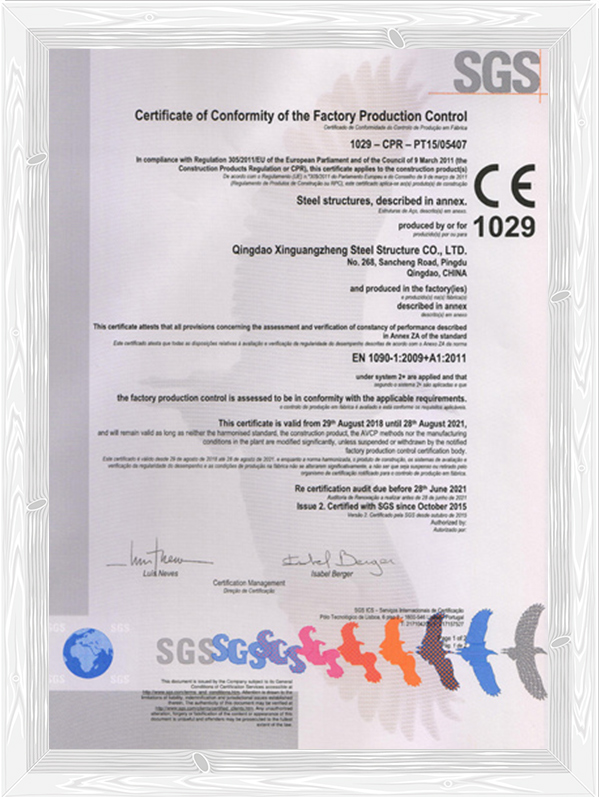

Qingdao Xinguangzheng Steel Structure Co., Ltd. is an enterprise specializing in the production of steel structure Bridges, steel structure workshop, exhibition hall, warehouse, assembly room, container room, intelligent animal husbandry equipment and other steel structure products. It has 25 years of experience and has obtained CE.ISO.BV and TUV certification.

The prefabricated steel structure building has the advantages of large spanning capacity, lightweight, fast construction speed, no leakage, and long service life. Its outstanding feature is to adapt to unsupported spans, suitable for warehouses, workshops, factories, exhibition halls, breeding plants, auditoriums, libraries, classrooms, lecture halls, cultural and sports venues, bazaars, residences, prefabricated building etc.

1) Rich expert group experience

Our employees with more than 20 years of experience have received professional training and testing. We can customize or design according to your drawings and requirements to provide satisfactory solutions.

2) Advanced tools

Equipped with more than 80 sets of precision repairing machines such as large-scale planers, automatic arc welding machines, assembly machines, sliders, and firing machines.

3) Strict quality control, check all product connections

Each workshop has some quality inspectors to inspect and evaluate the products.

4) Installed before sending

After assembling the first batch of products, test the assembly, and if appropriate, continue the assembly.

5) Timely delivery.

25 to 60 days after confirming the order, depending on the quantity of the product.

1. How to buy your idea products?

A: TT and L/C are acceptable and TT will be more appreciated. 50% deposit before producing, balance before loading by TT.

Project scope

1.Industrial plane/workshop/warehouse/factories, airport terminal, highrise building, bridge, exhibition hall, stadium and so on.

2.We can also develop and produce new parts according to your requirements.

2.What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 15 to 30 days.

3. How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

4.How to install after the goods arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

Qingdao Steel Structure Prefabricated Building Maritime Carnival Project

Project description:

The Qingdao Maritime Carnival project is located in Phoenix Island Tourist Resort, Huangdao District. It is an all-round multi-functional large-scale commercial, residential and tourism complex. The steel structure roof is constructed by Xinguangzheng.

Qingdao Xinguangzheng Steel Structure Co., Ltd. is an enterprise specializing in the production of steel structure Bridges, steel structure workshop, exhibition hall, warehouse, assembly room, container room, intelligent animal husbandry equipment and other steel structure products. It has 25 years of experience and has obtained CE.ISO.BV and TUV certification.

The prefabricated steel structure building has the advantages of large spanning capacity, lightweight, fast construction speed, no leakage, and long service life. Its outstanding feature is to adapt to unsupported spans, suitable for warehouses, workshops, factories, exhibition halls, breeding plants, auditoriums, libraries, classrooms, lecture halls, cultural and sports venues, bazaars, residences, prefabricated building etc.

1) Rich expert group experience

Our employees with more than 20 years of experience have received professional training and testing. We can customize or design according to your drawings and requirements to provide satisfactory solutions.

2) Advanced tools

Equipped with more than 80 sets of precision repairing machines such as large-scale planers, automatic arc welding machines, assembly machines, sliders, and firing machines.

3) Strict quality control, check all product connections

Each workshop has some quality inspectors to inspect and evaluate the products.

4) Installed before sending

After assembling the first batch of products, test the assembly, and if appropriate, continue the assembly.

5) Timely delivery.

25 to 60 days after confirming the order, depending on the quantity of the product.

1. How to buy your idea products?

A: TT and L/C are acceptable and TT will be more appreciated. 50% deposit before producing, balance before loading by TT.

Project scope

1.Industrial plane/workshop/warehouse/factories, airport terminal, highrise building, bridge, exhibition hall, stadium and so on.

2.We can also develop and produce new parts according to your requirements.

2.What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 15 to 30 days.

3. How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

4.How to install after the goods arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.